Discover the Best Practices for Effective Foam Control in Industrial Applications

Discover the Best Practices for Effective Foam Control in Industrial Applications

Blog Article

A Comprehensive Guide to Executing Foam Control Solutions in Your Operations

Efficient foam control is an important facet of functional effectiveness that typically goes ignored. Recognizing the ins and outs of foam generation can dramatically influence both efficiency and item top quality. This overview lays out the various challenges posed by foam and the diverse solutions offered, supplying a structure for choose and carrying out one of the most suitable approaches. By examining crucial elements such as application compatibility and personnel training, organizations can optimize their foam monitoring initiatives. As we explore these elements, the capacity for transformative enhancements in your operations becomes obvious. What actions will you take following?

Recognizing Foam Obstacles

Foam difficulties are a significant concern throughout various markets, influencing operational effectiveness and item top quality. The development of excessive foam can hinder procedures such as blending, transport, and storage space, resulting in raised downtime and waste. In fields like food and drink, pharmaceuticals, and petrochemicals, foam can hinder assembly line, creating item disparities and contamination dangers.

In addition, foam can obstruct devices capability, causing pricey repair work and upkeep. As an example, in wastewater treatment, foam can disrupt clarifier procedures, leading to lower therapy performance and regulatory conformity concerns.

Comprehending the underlying reasons for foam generation is vital for reliable monitoring. Elements such as surfactants, temperature changes, and agitation degrees can all add to foam manufacturing. Recognizing these components permits industries to apply targeted strategies that lessen foam formation while keeping product stability.

Kinds of Foam Control Solutions

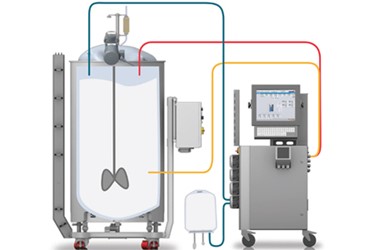

Mechanical options entail making use of tools such as foam skimmers or defoamers. These devices physically get rid of foam from the surface of liquids, consequently avoiding overflow and preserving optimal degrees in reactors and containers. Chemical services, on the various other hand, consist of the application of defoaming representatives-- substances that disrupt the foam structure, leading to its collapse. These representatives can be silicone-based, natural, or liquid, each offering unique advantages depending upon the application setting.

Finally, functional methods concentrate on process modifications. This may include customizing equipment specifications, such as temperature and pressure, or transforming the flow rates of fluids to lessen foam generation. Additionally, carrying out great housekeeping methods can also reduce foam development by decreasing pollutants that add to foam security.

Selecting the ideal foam control solution includes evaluating the details needs of the procedure, consisting of the kind of procedure, the qualities of the materials included, and safety considerations.

Selecting the Right Products

Choosing the right foam control items needs a comprehensive understanding of the particular application and its distinct obstacles. Aspects such as the kind of foam, the atmosphere in which it happens, and the preferred outcome all play crucial functions in product option. Foam Control. In industries such as food handling, it is necessary to pick food-grade defoamers that comply with safety policies while efficiently managing foam.

Additionally, consider the thickness of the liquid where the foam issue exists. Some products are developed for low-viscosity applications, while others are tailored for thicker liquids. Compatibility with existing processes is one more crucial aspect; the picked foam control representatives must integrate seamlessly without interfering with overall operations.

An additional vital variable is the technique of application. Some products may require dilution, while others can be applied directly. Evaluating the simplicity of usage pop over to this web-site and the called for dose can give understandings right into the product's efficiency and cost-effectiveness.

Application Strategies

Successful execution techniques for foam control remedies need an organized approach that lines up item option with functional needs. The initial step involves an learn this here now extensive evaluation of the processes where foam happens, determining particular areas that require intervention. By engaging cross-functional groups, consisting of top quality, design, and manufacturing guarantee, companies can gather understandings that notify the selection of the most effective foam control products.

Next, it is essential to develop clear objectives for foam reduction, ensuring that these goals are possible and quantifiable. This might entail defining acceptable foam degrees and the timelines for implementation. Training personnel on the residential or commercial properties and application methods of picked foam control agents is just as crucial, as appropriate usage is crucial for optimum outcomes.

In addition, integrating foam control services right into existing operations calls for mindful planning. Inevitably, a well-structured strategy will certainly improve functional performance while properly managing foam-related challenges.

Monitoring and Reviewing Performance

Monitoring and evaluating the efficiency of foam control solutions is important for guaranteeing that applied methods generate the preferred results. This process includes organized information collection and analysis to examine the performance of foam control representatives and methods. Key efficiency indicators (KPIs) ought to be developed prior to application, permitting a clear baseline against which to determine progression.

Examining effectiveness additionally needs periodic reviews of foam control treatments and representative effectiveness. This can be completed via sampling and testing, allowing drivers to identify if current options are meeting functional demands. It is vital to solicit responses from team participants who connect with these systems daily, as their insights can expose operational subtleties that quantitative data might neglect.

Ultimately, a structured tracking and analysis framework helps recognize needed modifications, making certain that foam control services remain efficient, inexpensive, and lined up with business goals.

Final Thought

In conclusion, effective foam control remedies are essential for optimizing functional effectiveness and preserving item quality. A complete understanding of foam challenges, combined with the option of suitable products and execution approaches, assists in the successful administration of foam generation. Spending and establishing quantifiable kpis in workers educating additionally enhance the efficiency of foam control steps. Normal tracking and assessment guarantee continuous renovation, inevitably resulting in a much more streamlined and efficient functional setting.

Implementing great housekeeping practices can additionally mitigate foam formation by decreasing impurities that contribute to foam stability.

Picking the best foam control items requires a thorough understanding of the specific application and its special difficulties (Foam Control).Effective implementation methods for check my source foam control services need a methodical technique that aligns item choice with operational demands.In conclusion, reliable foam control solutions are necessary for optimizing operational efficiency and maintaining product quality. A detailed understanding of foam challenges, integrated with the option of appropriate products and implementation strategies, promotes the effective monitoring of foam generation

Report this page